2020-11-4 14:58:19

2020-11-4 14:58:19 admin

admin

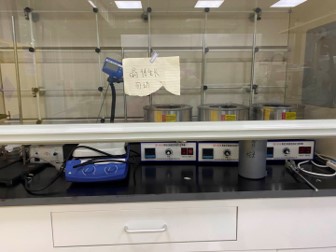

The spincoater is used to evenly distribute liquid films onto a substrate surface by spinning it at high speeds. This technique enables precise control over film thickness and uniformity, making it ideal for applications such as semiconductor fabrication, coating deposition, and surface functionalization. The hot plate, on the other hand, provides controlled heating, allowing for the removal of solvents, curing of films, or annealing processes. It enables the adjustment of temperature, providing a stable and controlled environment for various thermal treatments.